Metal forming in India – YSM

YSM

Established in 1979 – YSM today has evolved into the Top 3 global leaders in providing Stamping and Bending manufacturing solutions. Our greatest asset is not just an effective workforce, but our well-trained and competent support team of over.

Metal forming

Metal forming is a fundamental manufacturing process that involves shaping metal materials into various forms and dimensions. This process is crucial in numerous industries, including automotive, aerospace, construction, and more. It enables the creation of a wide range of products, from simple components like brackets to complex parts like engine components and aircraft wings. In this comprehensive explanation, we will explore the various methods of metal forming, its applications, and its significance in modern manufacturing.

Methods of Metal Forming:

- Bending: Bending is one of the most common methods of metal forming. It involves applying force to a metal workpiece, causing it to deform and take on a curved or angled shape. This method is used for creating components like brackets, pipes, and sheet metal parts. Bending can be done using various machines, such as press brakes and roll benders, depending on the complexity and precision required.

- Rolling: Rolling is a process that reduces the thickness of a metal sheet while increasing its length. It involves passing the metal between a series of rollers. This method is often used in the production of sheet metal and coils, which are further processed into various products like roofing materials, car body panels, and appliances.

- Forging: Forging is a metal forming method that involves shaping metal by applying compressive forces through hammering, pressing, or squeezing it while it’s heated or at elevated temperatures. This process improves the strength and durability of the metal. Forging is commonly used in manufacturing critical components such as crankshafts, connecting rods, and aerospace parts. There are different types of forging, including open-die forging and closed-die forging, each suited to specific applications.

- Casting: Casting is a metal forming method that involves pouring molten metal into a mold, allowing it to solidify and take the shape of the mold. This process is suitable for producing intricate and complex shapes. Casting is used in a wide range of applications, from producing engine blocks and turbine blades to creating decorative metal art.

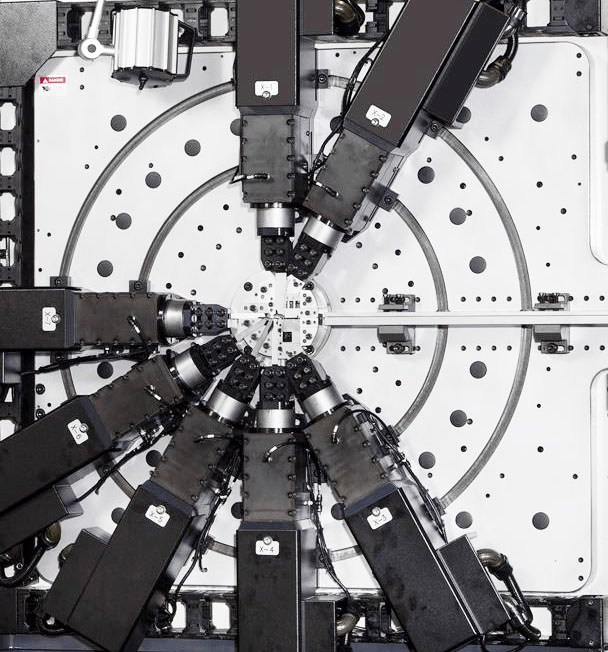

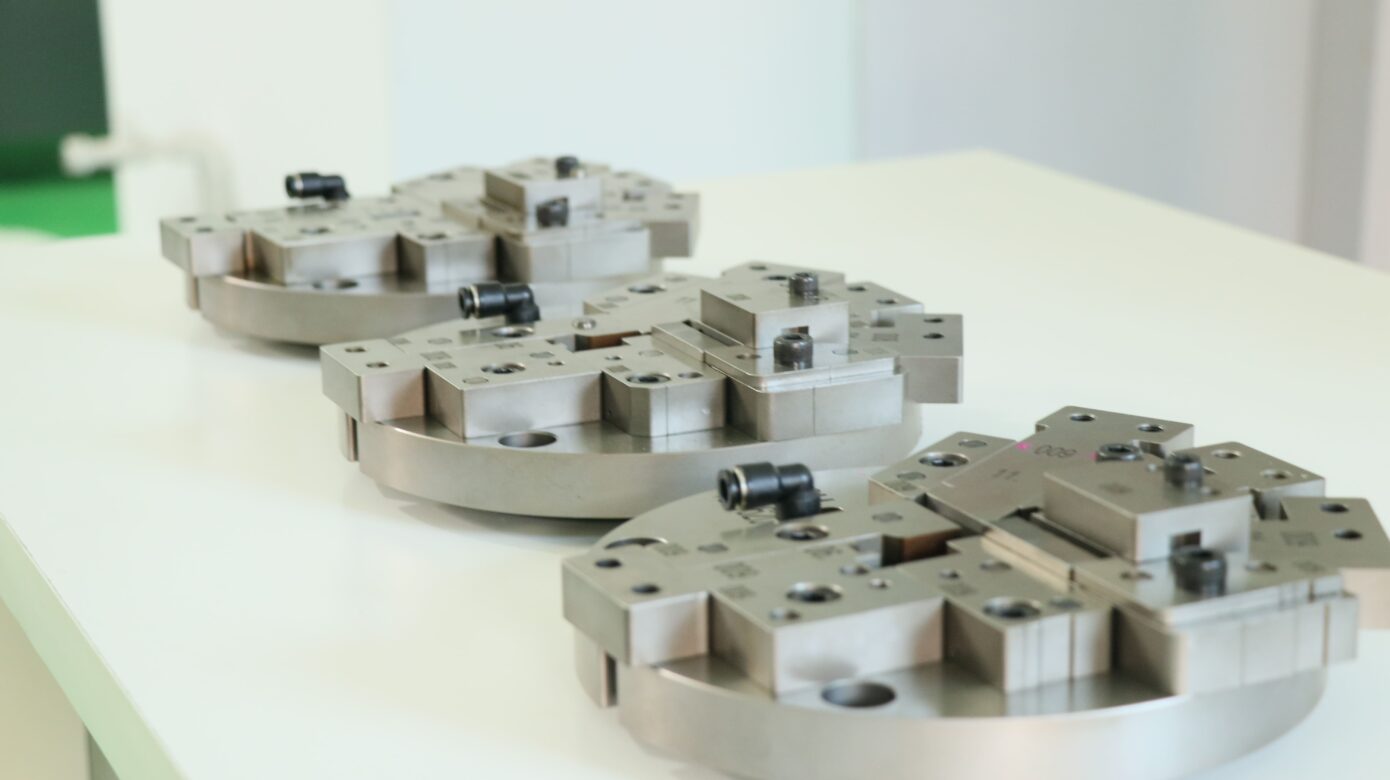

- Pressing and Stamping: Pressing and stamping involve using dies or molds to cut and shape metal sheets or coils into specific forms. The metal workpiece is placed between the dies, and a press exerts force to deform the material. This method is highly precise and is used to manufacture components like automotive body panels, electrical enclosures, and consumer appliances.

- Deep Drawing: Deep drawing is a specialized form of metal stamping used to create cylindrical or box-like shapes from flat sheets. It involves stretching and forming the material into the desired shape using a series of dies. Deep drawing is commonly employed in producing items such as kitchen sinks, beverage cans, and automotive fuel tanks.

- Extrusion: Extrusion is a metal forming process where a metal billet or preheated stock is forced through a die to produce long, uniform profiles. This method is used in manufacturing items like pipes, tubes, and architectural profiles. Extrusion allows for the creation of complex cross-sectional shapes and is highly efficient for mass production.

Applications of Metal Forming:

Metal forming is integral to the production of countless products across various industries:

- Automotive: Metal forming is extensively used in the automotive industry for creating body panels, engine components, chassis parts, and exhaust systems. The lightweighting trend has also led to the development of advanced forming techniques to reduce vehicle weight and improve fuel efficiency.

- Aerospace: Aerospace manufacturers rely on metal forming for producing critical components like turbine blades, landing gear, and structural parts. The high strength and precision achievable through metal forming are essential for ensuring the safety and performance of aircraft.

- Construction: Metal forming plays a vital role in construction, where it is used to fabricate structural beams, pipes, and architectural elements like facades and railing systems. The durability and strength of metal components are essential for withstanding the rigors of construction and providing long-lasting structures.

- Electronics: Metal forming is utilized in the electronics industry to manufacture components like heat sinks, enclosures, and connectors. These components are essential for heat dissipation, protection, and electrical connectivity in electronic devices.

- Consumer Goods: From kitchen appliances to furniture, metal forming is employed to create a wide range of consumer products. The versatility of metal forming techniques allows for the production of aesthetically pleasing and functional items.

Significance in Modern Manufacturing:

Metal forming holds immense significance in modern manufacturing for several reasons:

- Precision and Accuracy: Metal forming processes can achieve high levels of precision and accuracy, ensuring that components meet strict quality and performance standards. This is crucial in industries like aerospace and automotive, where safety and reliability are paramount.

- Material Efficiency: Metal forming processes often produce minimal waste compared to traditional subtractive manufacturing methods like machining. This efficiency contributes to cost savings and reduced environmental impact.

- Strength and Durability: Metal forming enhances the mechanical properties of materials, resulting in components with improved strength and durability. This is especially important in applications where structural integrity is critical.

- Cost-Effective Mass Production: Metal forming methods are well-suited for mass production, allowing manufacturers to produce large quantities of components efficiently. This scalability is essential for meeting the demands of various industries.

- Design Flexibility: Metal forming processes offer design flexibility, enabling the creation of complex shapes and geometries. This versatility allows engineers and designers to innovate and optimize product designs.

In conclusion, metal forming is a versatile and indispensable manufacturing process that shapes metal materials into a wide array of products used in everyday life and critical industrial applications. Its various methods, including bending, rolling, forging, casting, pressing, deep drawing, and extrusion, provide manufacturers with the tools to create precise, durable, and cost-effective components across multiple industries, driving innovation and progress in modern manufacturing.